Executive Summary. Most decisions can be further analyzed by collaborative or self-inquiry. When looking for ways to decrease costs, ask yourself 27 questions. And by the way, you have to make up the questions.

Two variables in the profitability equation. Increased profitability comes from changing the value of one of two variables: the money collected must increase or the money must decrease. Here let’s talk about ways to decrease cost.

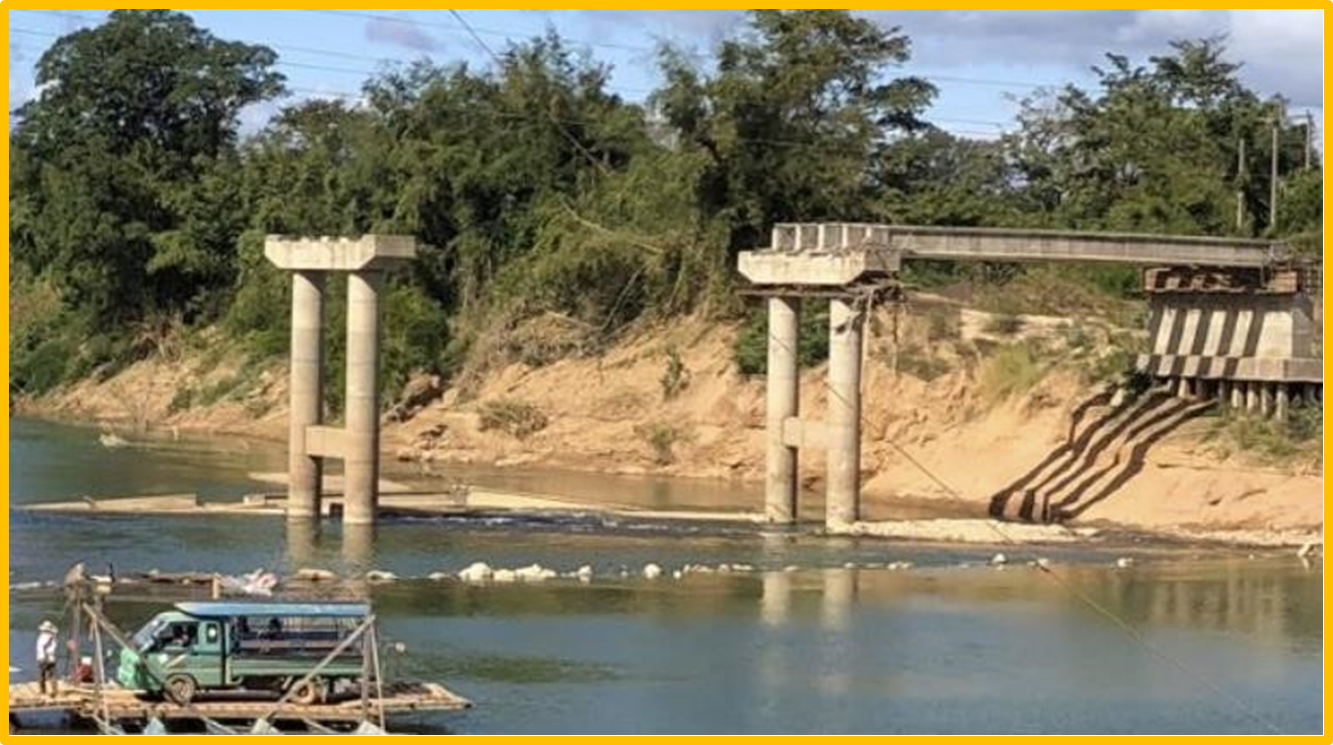

Rule of 27. There’s a way to decrease cost in everything bought on a construction jobsite. The obvious way is “three quoting” (getting at least three quotes and taking the low bidder). That method aside, how else can we drive the cost of our products purchased to a lower value? Precast beams in Laos (after a washout). The avenues to cheaper costs lie in your brainstorming success. Whether it’s collaboratively as a group, or just you on your own, you can come to 27 ways to decrease cost. Even if only one of them is successful, you’ve still cut cost at a minimum of effort. I developed these questions in six minutes for precast beams for a bridge job:

Rule of 27 – Precast Beam Purchase

- What are the materials that comprise a precast beam?

- Can we get the water cheaper?

- Can we get the cement cheaper?

- Can we get the aggregate cheaper?

- Can we get the strand cheaper?

- Can we modify the strength of the rebar or strand and decrease steel?

- Can embeds (for overhang brackets) be included in the price of our beams?

- Can we fabricate it off site? (this is likely the case for >95% of all projects)

- Can we fabricate it in a cheaper shop?

- 10.Can we fabricate it closer to the site to reduce driving cost?

- Can we go with a different material (i.e. steel or timber)?

- Can we provide the P.E.-seal, or can they (at a reduced price)?

- Can we offer a more efficient design based on the fabricator’s design selections in the yard?

- Can we install it cheaper?

- Can we use our own crane?

- Can we use someone else’s crane?

- Is one crane, or two cranes, cheaper and/or quicker?

- Can we install at night, or on a weekend, or a holiday?

- Can we get a better trucking rate?

- Can we provide pilot cars at our cost?

- Can we make a combination deal with our trucker on this job and another job he has with us?

- Can we use a different machine other than a crane (like a barge or a forklift) for hoisting?

- Can we use different rigging, or include rigging in the cost of the beam?

- Can we arrange better terms on the purchase?

- Can we pay a deposit up front?

- Can we negotiate/offer a Net 10, 5% discount on payment?

- Can we get a discount on storage at the yard?

The goal of this exercise is to get you and the group thinking. To change a behavior. To generate muscle memory – the muscle here is your brain, and training it to think of cheaper ways to get things.

This is a process that can be used during bidding or, as above, during the job execution. And it can be used in many types of decisions such as which form system to use, which subcontractor to sign up, and which crew to use on a job. Keep drilling down to new ideas by asking and asking and asking questions.

My story. I did a project in Waikiki where there was a requirement to install sheetpiles, and leave them in place. Most contractors, in my experience, like PZ and AZ sheets. However, on this job, the specification said to install a sheet with a certain section modulus. The engineer didn’t care about water tightness, so the thread type had to be good enough to simply drive in place and then be backfilled against (we we’re under the water table, so we didn’t care about water intrusion). It was a great win for us – we made about $100,000 on the buyout of the sheets. It was near zero effort (a little bit of calling around), and didn’t affect our schedule. It also didn’t take 27 questions to get to this solution, but the principle of the process was the same – “how can I achieve the design intent for less money?”

My story. I did a project in Waikiki where there was a requirement to install sheetpiles, and leave them in place. Most contractors, in my experience, like PZ and AZ sheets. However, on this job, the specification said to install a sheet with a certain section modulus. The engineer didn’t care about water tightness, so the thread type had to be good enough to simply drive in place and then be backfilled against (we we’re under the water table, so we didn’t care about water intrusion). It was a great win for us – we made about $100,000 on the buyout of the sheets. It was near zero effort (a little bit of calling around), and didn’t affect our schedule. It also didn’t take 27 questions to get to this solution, but the principle of the process was the same – “how can I achieve the design intent for less money?”

Work safe!

0 Comments