Executive Summary. The difference between bid day pricing and change order pricing is miles apart because of one factor. Learn this factor and certain red flags to look for when working for an Owner.

What’s the major difference? There is one major difference between contractor estimating on bid day, and then estimating for change orders. The difference is that the Contractor only had to be low bidder on bid day. Now that the job has started, and it’s change order time, he or she has no requirement to compete for the work. He or she will be negotiating the highest price possible for the work.

Reality of change order pricing. The reality is that, to a certain degree, the Contractor has the advantage. There isn’t a bid opening to find the lowest price for the changed work – the Contractor simply has to pass the “fair and equitable” standard in his/her pricing. And as an Owner’s representative, you must ensure this.

As an owner, give me some red flags! Here are some red flags and some help on understanding what’s going on from the Contractor’s standpoint:

- Unfair credits – this one is easy. Seems that contractors are pretty good at remembering items in the changed scope of work that cost additional money. A good construction manager seeks the credits in the work.

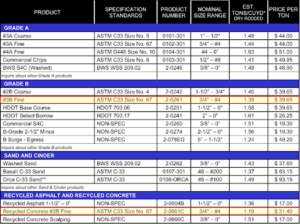

- Substitutions – contractors will sometimes suggest use of Product B instead of Product A. The reasons vary. Lately, the reason has been availability due to Covid or inflation. However, often times the contractor knows that the cost of Product B is just cheaper, and that it can satisfy design intent. So, the Contractor will RFI a request to use a substitute product. Take for example the cost of aggregates at left. If the Contractor had to buy 10,000 tons of #3B Fine material, and instead of using the mined material from the earth, he/she could convince the Owner to use recycled material, that’s a savings of 10,000 tons * ($39.65/ton – $31.40/ton) = $82,500. If this goes uncaught by the Owner’s representative, that’s a missed opportunity for the Owner to save money on their project.

- Unbalancing of bid items – some contracts have the requirement to use the unit prices from a proposal in the negotiation of changes. This can be a double-edged sword because an unbalanced bid time varies in the party it benefits (or hurts). Sometimes bid items are unbalanced just to be “rounded” to an easy number, and sometimes they’re unbalanced to take advantage of errors on the proposal quantities, or expected overages and underages in quantities once the project is underway.To explain unbalanced pricing, it is likely easier to explain what balanced pricing is. Each bid item has a direct cost – this is the cost of Billy and Joey to install the 5,000 square feet of ceiling tile. However, this direct cost does not include the other costs like overhead and other markups. A balanced unit price on a proposal form has the exact percentage of overhead and markup that the overall proposal has. So, in other words if the job as a whole has a total overhead and markup of 31%, each and every bid item would be 31% greater than the actual direct cost.

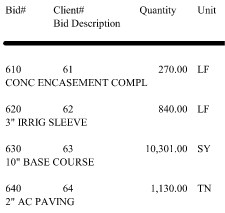

What you’re seeing below is a good example of unbalancing. The Balanced Bid Unit Price is the price the Contractor is “supposed to” bid the job at. The Bid Price is the actual price turned into the Owner on his bid form. See bid items 61, 62, 63, and 64 below:

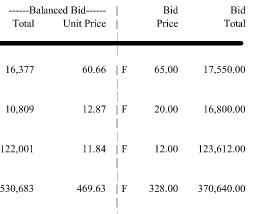

Unless you are an Owner who has escrowed the entire bid and is able to pull the data displayed above, you’ll never know which items are over and underbalanced by the Contractor. This is where a good independent cost estimate and an honest contractor come in. - Lessened or modified scope – the substitution discussed above is similar, in principle, to this technique. Here the Contractor play is to satisfy design intent by not doing, or doing less, of what the Contractor’s budget has.Below is a 100’ x 100’ slab with construction joints as shown in red and blue:

- 24” thick slab on grade perimeter.

- CJs per original plan (200 LF).

- CJs per original plan (400 LF).

- Total CJ length = 600 LF.

There are two types formwork here: edge slab in black, and construction joint in blue and red. Both cost money in labor (and, to a lesser degree, material). The Contractor often tries to reduce their labor effort on the project by NOT DOING something.

So, again, here is the Contractor play in his/her RFI: “Hey Owner, do we really need all these construction joints? How about we remove the red ones – this’ll give you jointing on 50’ centers and that’s really good enough.” When the Owner agrees to this, the Contractor picked up 400 LF, or 800 SF, of forming at $40/SF (total labor and material saving by the Contractor of $32,000. Again, is there some way an Owner can participate in this savings, or flat out take the entire credit?

My story. I’m giving a presentation on these techniques, and a couple others, in the coming days. There will be owners and contractors in the audience. So, half of the attendees will want to come up and high five me after the presentation (the owners) and the other half will want to take me out back to the wood shed (the contractors). Wish me luck.

Work safe! (Oh, and yes, I’ve done each of these. And seen them all “done to me”.)

0 Comments