Executive Summary. Collecting data from a construction jobsite can serve many purposes, and all of them very beneficial. Uses such as claim defense, quality assurance, and company improvement are just a few. You have no excuse not to gather this data – it’s easy! And practically free.

We can’t afford these $100,000 scanning equipment purchases. Many readers of this article work for small construction companies that do not have large budgets for purchases, such as these multi-ten thousand dollar type lidar machines on tripods. Or BIM tools which provide virtual and mixed reality experiences in desktop software or goggles you wear on your head on the jobsite. You can gather data just fine, and with as much credibility as these fancy tools. And by the way, the pyramids were built without these tools, so there’s proof that we can get the data.

We can’t afford these $100,000 scanning equipment purchases. Many readers of this article work for small construction companies that do not have large budgets for purchases, such as these multi-ten thousand dollar type lidar machines on tripods. Or BIM tools which provide virtual and mixed reality experiences in desktop software or goggles you wear on your head on the jobsite. You can gather data just fine, and with as much credibility as these fancy tools. And by the way, the pyramids were built without these tools, so there’s proof that we can get the data.

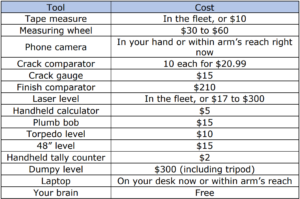

Where are these cheap tools? They’re already in your fleet and paid for, or are four miles away at the local hardware store in Aisle H. Here are some basic tools which get the job done:

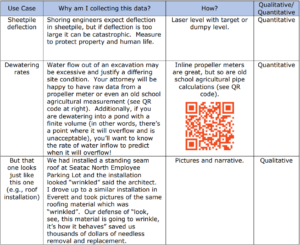

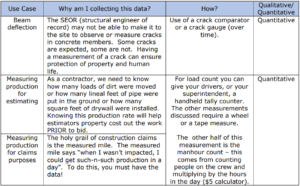

Qualitative or quantitative? These are the two types of data we are collecting.

Qualitative data shows differences by way of a narrative or by a picture. The painted wall mockup is a good example. For many jobs, the architect wants to see an example of the final product and only after his/her viewing and touching of the sample can he/she make the call on whether or not the installation is acceptable. Some architects will also bring out finish comparators which are a collection of rubber placards giving examples of finish roughness (the QR code at left is used in concrete repair roughness).

Quantitative data collects measurements of some sort: a length, a deflection, a volume, a speed, a weight, et cetera. These all result in numbers and facts, not words and opinions.

Let me give some examples:

My story. This article goes hand-in-hand with the field sketch article I wrote. I just can’t emphasize enough the importance of collecting data. Especially if you’re a reader who has an engineering degree – every guy in the field is expecting you to do this. The owner of the company you work for is expecting that $200,000 degree to have at least brought him a field sketch and a graph showing varying dewatering rates over time (yes, you can plot the flow rate on the y-axis and the date on the x axis and let the data run over time baby!).

My story. This article goes hand-in-hand with the field sketch article I wrote. I just can’t emphasize enough the importance of collecting data. Especially if you’re a reader who has an engineering degree – every guy in the field is expecting you to do this. The owner of the company you work for is expecting that $200,000 degree to have at least brought him a field sketch and a graph showing varying dewatering rates over time (yes, you can plot the flow rate on the y-axis and the date on the x axis and let the data run over time baby!).

Here’s more advice – data’s better than guessing. “The deflection was pretty big” doesn’t work too well. Now maybe if you’re going to use that agricultural pipe method above you may get some criticism of the measurement being inaccurate; however, it is a start and absent any other means of measuring, it’ll establish a credible estimated basis.

Having this data allows for jobsite management to make smart decisions and attorneys to have the necessary information to forward a claim on your behalf.

These methods and these tools are simple to use and inexpensive. There’s zero excuse not to gather data to protect your company, protect workers and property, or to better your organization. Young engineers out there go be an engineer, and superintendents go tell your field engineer to do his/her job!

Bonus: From the “I’ll say it for the Company Owner” manila file: Employers don’t want to hear the whole “you should drop the $100,000 on such-n-such tool, it’ll save so much money”. This comment is always made by a person not cutting the check. Yes, it’s true, the tool can save a lot of money, but every owner is thinking, “can’t we just build it right the first time? Scott listed all the tools you need above which we already have or can be bought with $500. Be an engineer.”

Work safe!

0 Comments