Executive Summary. The designer knows design. You know cost. If you can satisfy the designer at a fraction of the cost, this equates to an increased bottom line for you.

Know the designer’s worry. Designers worry about their designs standing the test of time. They worry about failure, excessive maintenance, or general client dissatisfaction. They worry about getting standard of care claims from owners. Keep that in mind because, generally speaking, they couldn’t care less about saving you money. They don’t want to lose their license or get sued.

Know design intent. Whether you went to engineering school or not, you can figure out pretty quickly after having built structures what the needs are of a project. Structures can’t fall, pipes can’t break, windows can’t leak, and paint can’t peel. Knowing these things are paramount to the designer. Use the knowledge of yourself, your subcontractors, and you vendors to maintain quality, but for less cost.

Isn’t this just value engineering? Yes, but no. In a way, yes, this is value engineering. But just not called that when you make the ask.

Let me give an example. Instead of using 316 stainless steel on a pipe support, you can suggest 304 stainless steel. This may have both the minimum properties in strength and corrosion resistance to satisfy design intent, but at $50,000 less cost. But here’s the difference between value engineering and a simple ask to make a change in a material: in a value engineering specification, you usually have to share in the savings in some way (say 60/40). When you approach the Engineer with a “how about 304 stainless instead of 316 stainless?”, it’s more covert. He or she doesn’t know that it’s saving you big money, and frankly, he or she doesn’t care because it satisfies the design intent and they’re still sleeping at night knowing that their facility if functioning satisfactorily.

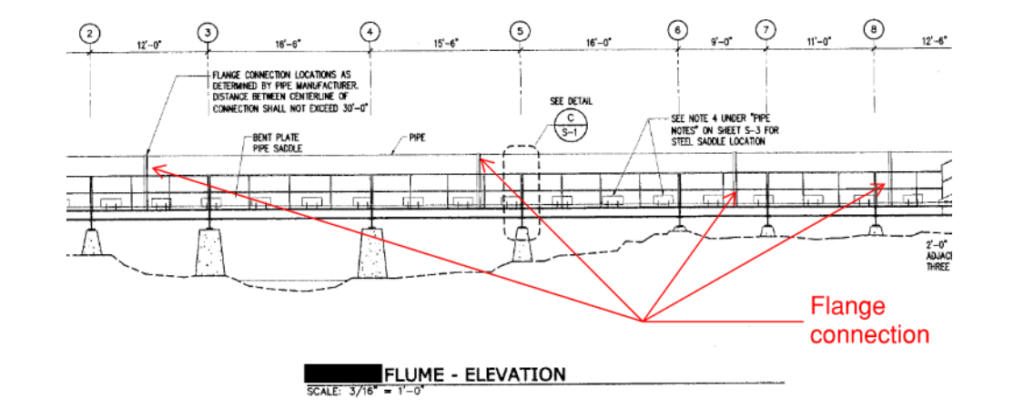

My story. I had a job once to run a 48” HDPE line across a ten span little existing bridge (see drawing on next page). The owner’s design called out for four flange connections across the bridge. When I went to order the pipe from the supplier he asked “why do you have four flange connections here, we could save you $45,000 if you could eliminated a flanged fitting?” So, I made the submittal for one less flange fitting and it was approved. I satisfied design intent by moving the water across the bridge using HDPE. And on an $800,000 project, we added $45,000 to the bottom line. Not bad.

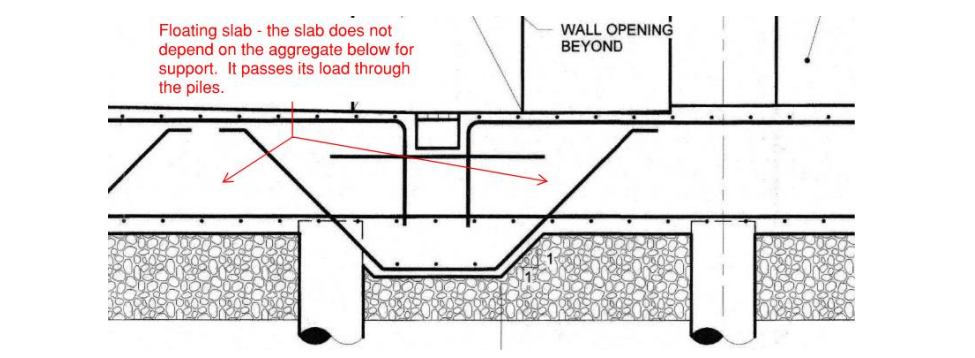

Another example is the aggregate layer under floating structural slabs. We call them “floating” because the slab is designed NOT TO RELY on the aggregate base course to support it. Therefore, the primary purpose is to provide a clean working surface for the rebar and concrete crews. Often times the Project Specifications call out the aggregate layer to be imported granular fill or base course. There’s two possible avenues of cost savings here which still satisfy design intent: (1) decrease the thickness of the aggregate layer and/or (2) change from imported aggregate to a recycled aggregate like crushed concrete. Both increase profit!

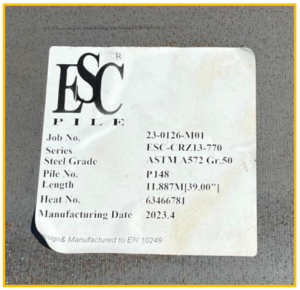

The last example – minimum design properties. I had a job once to provide a sacrificial sheetpile wall. The engineer of record called out something like “Contractor shall use an AZ 26 sheetpile with minimum section modulus of 48.4 in3.” Well, as you may or may not know, section modulus (designated as “S” in

structural engineering) is a steel/wood/aluminum shape’s ability to resist bending before failing – it’s a simple calculation using just the geometry of the section. Go ahead and Google any sheetpile properties table, it’s in there! The higher the S, the stronger the sheet. Well, I surmised that the Engineer only knew of AZ sheets (this is very common in the United States). But I thought, what if I can find a cheaper sheet with this minimum section modulus. I did. I found this oddball sheet with an S greater than the AZ 26 and put $100,000 to the bottom line – a win for the Engineer and for the Contractor!

Work safe

0 Comments